ADVANCED RESOURCES INC.

PROVIDING OEM SOLUTIONS FOR NOISE, VIBRATION & HEAT CONTROL

SOUND ABSORBERS

These products include acoustic foams, fibrous absorptive materials, perforated and micro-perforated panels, used to reduce reverberant noise on ground vehicles, ground equipment.

Complies with various indepent test standards including:

- FMVSS 302

- UL 94

- UL2200

- Mil-Specs

- BMS8-385C

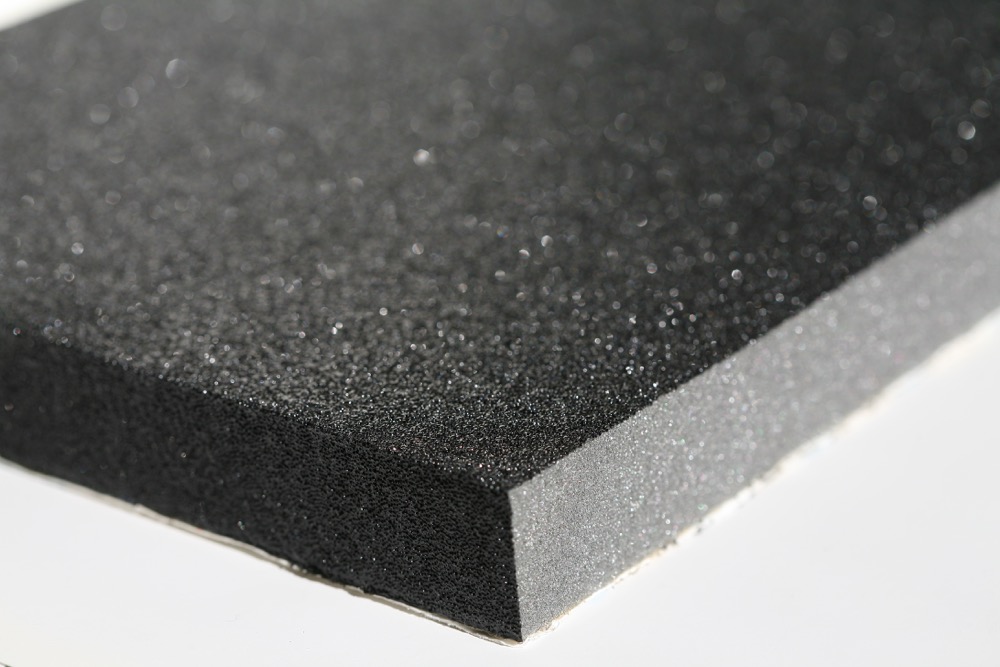

Soundfoam® is a family of sound absorbing materials designed for each specific OEM markets requirements.

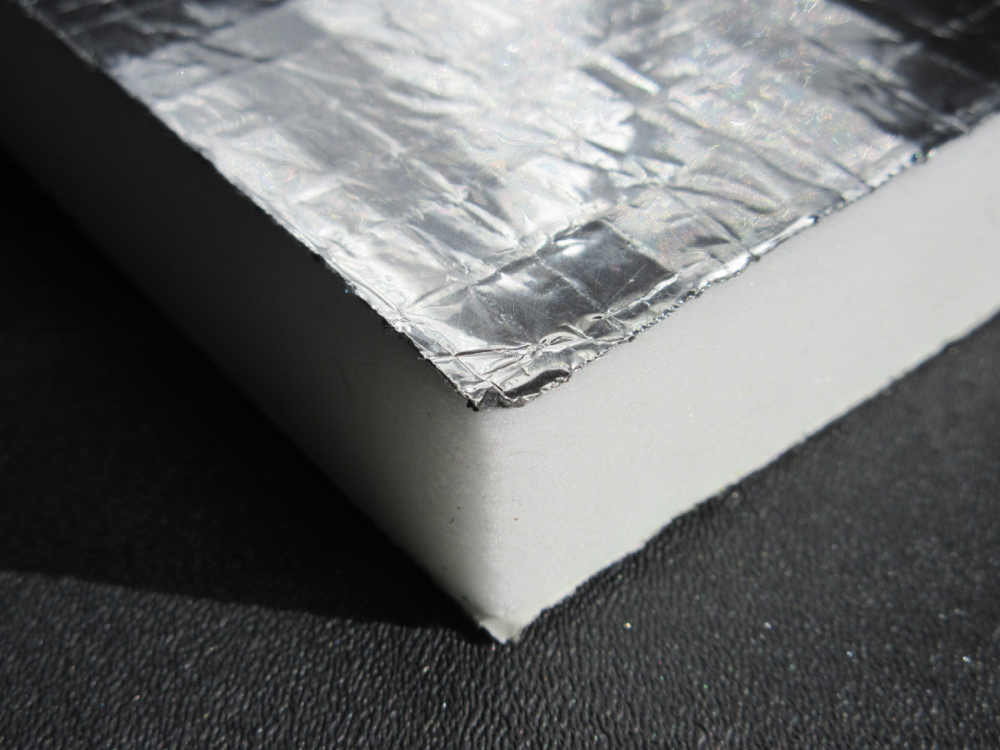

Offered with attractive and durable coverings and face treatments including 100% encapsulation for enhanced product life and performance.

Offered in various thicknesses from 1/8” to 4” in sheets, rolls or fabricated parts, and PSA.

- Easy installation with factory applied pressure sensitive adhesive backings.

- Polymer selection includes: polyurethanes, melamines, polyimides, polyethylene, epdm, and polyester.

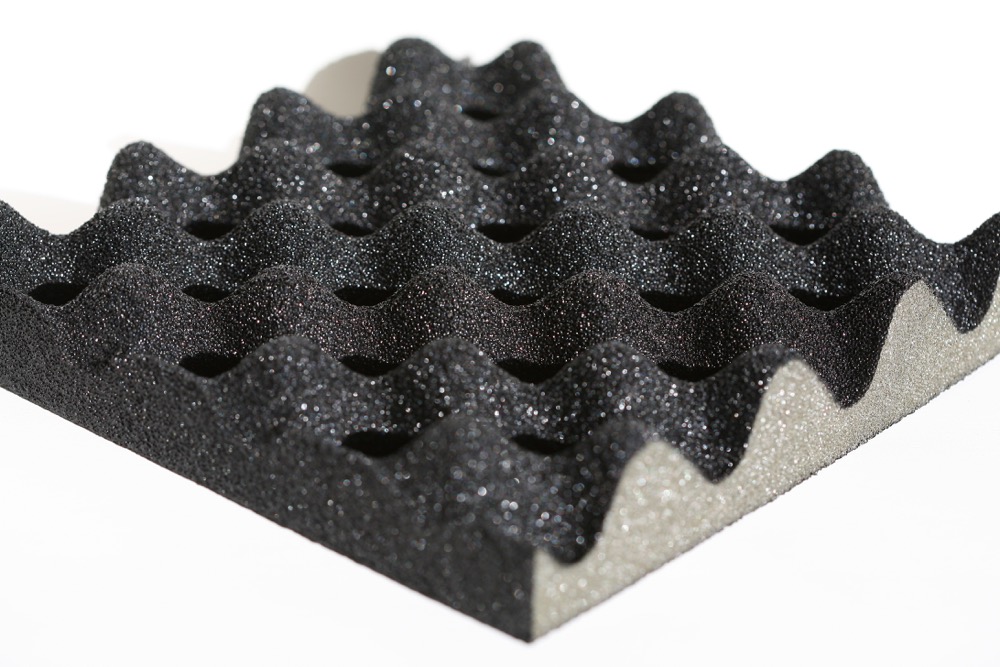

Sound Absorption materials are most effective when they can be applied in the same room/enclosure lining as where the noise source is located. Sound Absorbers reduce reverberant airborne noise energy (echo) by being placed in front of reflective surfaces. Critical selection criteria include knowing the dominant noise frequencies of the noise source(s), thickness of the Sound Absorber, it's flow resistance with the proper acoustic impedence match with the absorber's top surface.

*Contact ARI for assistance in selecting the proper Sound Absorber, the amount of effective coverage, as well as placement and attachment.

Contact ARI for assistance in selecting the proper Sound Absorber, the amount of effective coverage, as well as placement and attachment.

Please visit our associates at Noise & Vibe for Industrial and Architectural inquiries.